Graphene material produced starting from GO with chemical reduction process to removal the oxygen-containing functional groups, will be called reduced graphene oxide (rGO). The rGO powder is obtained by vacuum freeze- dried process. In some applications, GO to rGO's reduction is done during the material composite process.First, using GO's good surface wettability for dispersion, then in-situ reduction is carried out to achieve the composite of different materials. RGO's surface defect site is relatively lesser than GO and it is more close to single-layer graphene in structure and property.

Technical Advantages

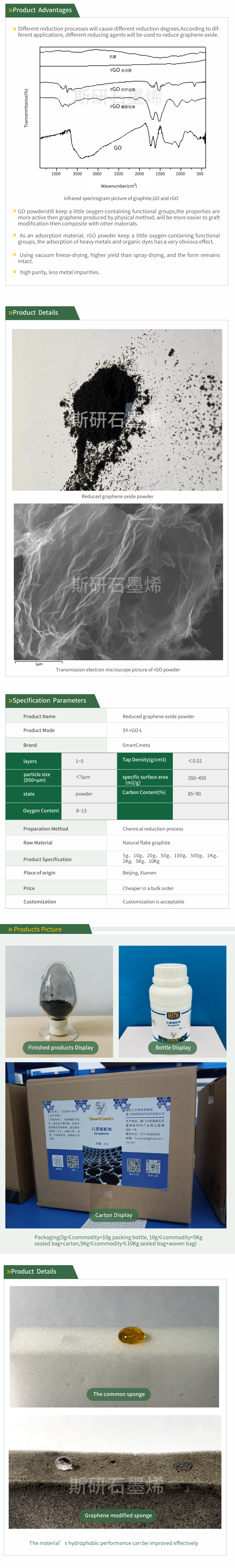

- Different reduction processes will cause different reduction degrees.According to different applications,different reducing agents will be used to reduce graphene oxide;

- RGO powder(with chemical reduction process) still keep a little oxygen-containing functional groups,the properties are more active then graphene produced by physical method, will be more easier to graft modification then composite with other materials;

- As an adsorption material, rGO powder keep a little oxygen-contain- ing functional groups, the adsorption of heavy metals and organic dyes has a very obvious effect;

- Using vacuum freeze-drying, higher yield than spray-drying,and the form remains intact;

- High purity, less metal impurities.